In the research project "reFuels - Rethinking Fuels", the entire value chain of renewable fuels was examined from 2019 to 2022 - from production and distribution to practical use in different types of vehicles. For an interactive insight into the project, click on the image opposite.

Renewable fuels, known as reFuels, offer a climate-friendly alternative to fossil fuels and are therefore a sensible addition to electromobility. They can reduce CO₂ emissions by up to 90 percent over the entire life cycle - without having to retrofit existing vehicles or infrastructure. In order to tap into this potential, KIT has been working for several years with partners from industry, politics and science to produce these innovative fuels efficiently and economically.

The most important findings at a glance:

- For the first time, larger quantities of synthetic diesel and gasoline fuel were produced from renewable energies.

- The technology for producing the reFuels products was refined and further developed and their carbon and energy efficiency significantly increased.

- In addition, the developed fuels were tested in vehicles with today's combustion engines. A haulage company in southern Germany drove over a million test kilometers with a fleet of different types of trucks using the reFuels fuel.

- In order to enable larger-scale production and the market launch of reFuels, a concept for a demonstration plant on a refinery scale was developed.

- Finally, the quotas for blending into conventional fossil fuels were increased to 100 percent, resulting in a "reFuels pure fuel".

- All relevant factors, from production processes to costs and product properties through to environmental influences, were evaluated holistically for the first time.

- All interest groups, from industry to trade associations, politics, NGOS and consumers, were informed and involved in the research process through discussion events and workshops.

Building on the reFuels results, the InnoFuels project was launched in February 2023: The platform project, which is funded by the German government, is working on the prerequisites for the rapid ramp-up of the production of renewable fuels. The aim is to network the many national and European research projects on the topic. The collaboration should help to accelerate the production of larger quantities of electricity-based liquid fuels and advanced biofuels.

Alongside other German research institutes, the reFuels project teams are also actively involved in this platform.

News and updates

What's new with us? Here we share current topics, insights into our work, and previews of upcoming activities.

To what extent do the greenhouse gas emissions resulting from the production and use of fuels from fossil and renewable sources differ? A new compilation of literature from the InnoFuels project, more precisely from the Road & Rail team, provides a compact overview of current findings and methodological approaches. The focus is on central terms and methods of GHG balancing, in particular the life cycle assessment methodology according to ISO 14040/44 and its application within the framework of the Renewable Energy Directive (RED). The overview is supplemented by exemplary emission values from our own calculations and the RED, which illustrate important influencing factors and sensitivities.

Learn more

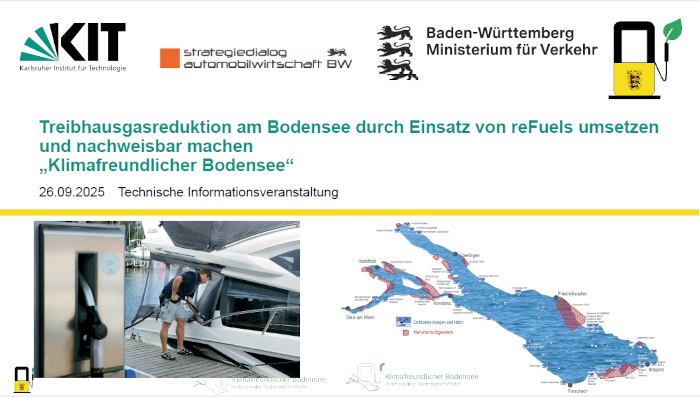

At Interboot 2025, we gave a compact presentation on the opportunities that Nautic E10 and Nautic HVO offer for businesses, customers and the environment. Our slides show how the use of these fuels can be easily implemented in practice and provide suggestions on how you can effectively present and advertise your reFuels consulting and service offerings. The focus was particularly on practical tips and ideas on how you as a company can offer competent advice and provide your customers with the best possible support when switching to sustainable fuels. Take a look at our presentation - it provides valuable impulses for service, marketing and customer communication on the subject of renewable fuels.

Learn more

On 28 October, an internal online workshop will take place as part of the InnoFuels project, which will focus specifically on the internationalization of sustainable fuels. Stakeholders from Switzerland and the Netherlands will be among those taking part. International activities, innovative approaches and funding opportunities will be highlighted and discussed together. With this event, the project partners are demonstrating how important international exchange is for the further development of climate-friendly fuel solutions. The aim is to involve new stakeholders worldwide in order to accelerate progress. In general, chemical parks such as the Infraserv Höchst site in Frankfurt am Main also play an important role. They offer ideal conditions for providing the necessary infrastructure for implementation.

Learn more

At NUFAM in Karlsruhe, everything at the Karlsruhe Institute of Technology (KIT) stand revolved around the future of sustainable fuels. With the reFuels, InnoFuels and REF4FU projects, visitors were able to discover how electricity-based and advanced biofuels are finding their way into practice - exciting for research, companies and politics alike. KIT was also present on stage: specialist presentations and a lively panel discussion focused on opportunities, challenges and concrete solutions for climate-friendly mobility. With these contributions, InnoFuels was able to successfully showcase its role as a platform for research, networking and transfer in the field of sustainable fuels at NUFAM.

Learn more

At the beginning of August, Baden-Württemberg State Secretaries Florian Haßler and Patrick Rapp visited the Ultramarin filling station in Kressbronn. As part of a state project, the regenerative fuel HVO (Hydrotreated Vegetable Oil) is being offered there for private ships - with a proven greenhouse gas reduction of 87%. This is made possible by the conversion of the marine filling stations to reFuels and the digital connection to fuel data, implemented in cooperation with Bosch. Even if InnoFuels is not directly involved here, such pilot projects are important signposts: they show how technology, politics and practice can work together to massively reduce CO₂ emissions.

Learn more

The bioliq® project at KIT, which was completed at the end of last year, demonstrated early on how residual biomass such as straw can be converted into synthetic fuel - a technological milestone that is also highly relevant for current projects such as InnoFuels or Refinnieries for Future (Ref4FU). The process chain comprises the shredding and drying of residual biomass, its thermochemical conversion via fast pyrolysis, the central gasification and purification of the synthesis gas and the subsequent chemical fuel synthesis. And all of this on an industrial scale. In this interview, project manager Prof. Nicolaus Dahmen looks back on the most important stages, challenges and successes of bioliq ®.

Learn more